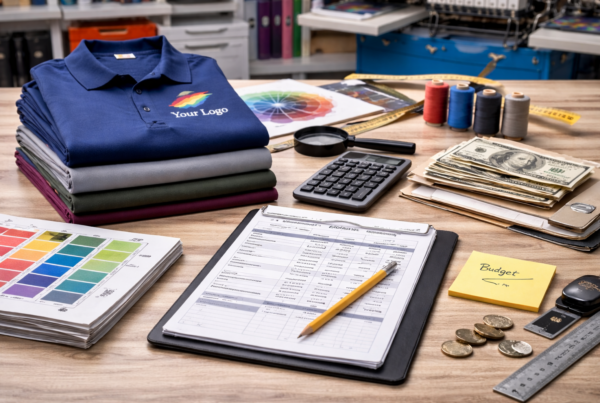

When you’re ordering custom apparel, being “print-ready” doesn’t mean you need to be a designer or have everything perfect on day one. It simply means your artwork, garment choices, and expectations are aligned in a way that allows production to move smoothly — without delays, surprises, or extra costs.

Here’s what “print-ready” really means, and how to get there.

What Does “Print-Ready” Actually Mean?

A print-ready order is one where:

-

The logo or artwork is usable at production quality

-

The garment selection matches the decoration method

-

Placement and sizing are clearly defined

-

Approvals can move forward without repeated revisions

When these pieces are in place, your printer can focus on what they do best: delivering high-quality results.

Logo Files: The Foundation of a Print-Ready Order

Your logo doesn’t need to be perfect — but it does need to be usable.

Best file types

-

Vector files (AI, EPS, PDF) are ideal

-

High-resolution PNGs or PSDs can often work

Common issues that slow things down

-

Low-resolution images pulled from websites

-

Logos saved as screenshots

-

Tiny details that won’t translate well to fabric

If your file needs cleanup, a professional printer can usually help — but starting with the best version you have keeps things moving.

Color Choices That Translate to Fabric

Colors behave differently on fabric than on screens.

Being print-ready means:

-

Understanding how light or dark garments affect ink color

-

Knowing when a logo needs adjustment for contrast

-

Trusting printer recommendations for ink or thread colors

This isn’t about changing your brand — it’s about making sure it looks right in real life.

Choosing the Right Decoration Method

Not every logo works the same way across all decoration styles.

-

Screen printing is great for bold designs and larger quantities

-

Embroidery works best for simpler logos with clean shapes

-

Small text or fine detail may require adjustments depending on the method

A print-ready order considers how the design will be applied, not just what it looks like on screen.

Clear Placement and Sizing = Fewer Revisions

One of the easiest ways to stay print-ready is clarity.

Helpful details include:

-

Left chest vs center chest vs full back

-

Approximate print size (small, medium, large)

-

Consistency across sizes and garments

The clearer the placement, the faster approvals happen.

Garment Selection Matters More Than You Think

Different fabrics absorb ink and thread differently.

Being print-ready includes:

-

Choosing garments appropriate for the use case

-

Understanding how fabric weight affects print results

-

Being flexible if a specific style is backordered

A good printer will guide you — especially if comfort, durability, or branding consistency matter.

Approvals Are Part of the Process (Not a Delay)

Proofing isn’t a slowdown — it’s protection.

A print-ready order allows time for:

-

Reviewing digital proofs

-

Confirming colors and placement

-

Making small adjustments before production

Rushing past this step often leads to regret later.

Print-Ready Doesn’t Mean “Perfect”

You don’t need:

-

Final artwork on day one

-

Industry knowledge

-

Design software experience

You do need:

-

Clear goals

-

Openness to feedback

-

A printer who knows how to guide the process

That’s where experience makes the difference.

Final Thoughts

A print-ready order isn’t about perfection — it’s about preparation. When your artwork, garments, and expectations are aligned, the entire process becomes smoother, faster, and more enjoyable.

And the end result? Custom apparel you’re proud to put your name on.